Galvanizing lines for wire

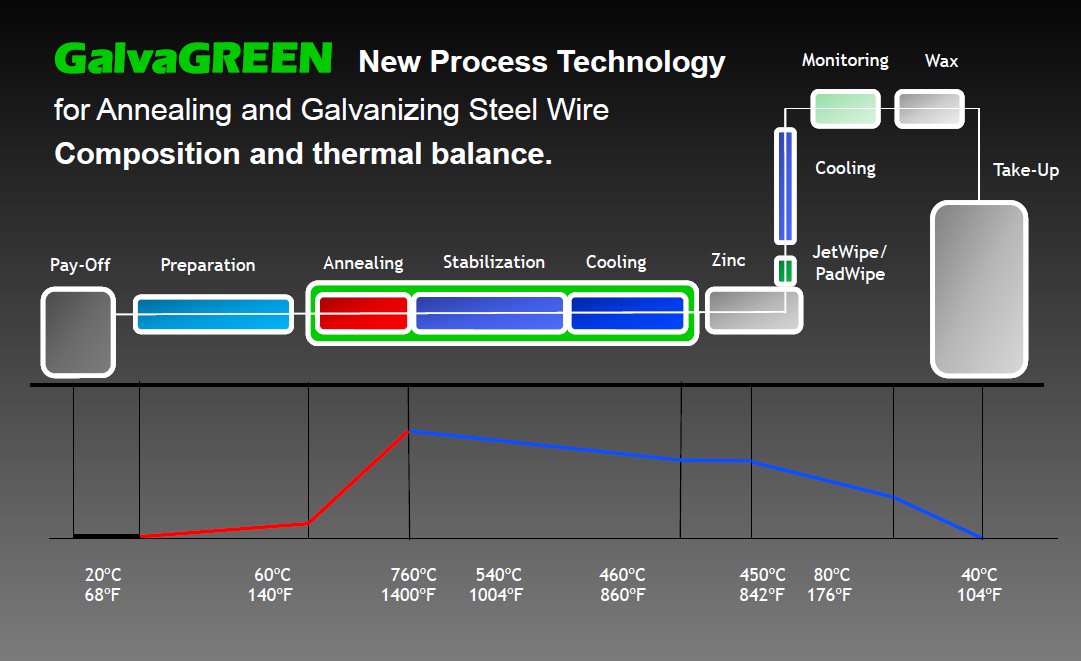

GalvaGREEN, Ecological Annealing And Hot-Dip Galvanizing Lines For Wires

- No ACID HCL

- FLUX is not used

- Energy saving due to higher efficiency of the furnace(s).

- Speed up DV400

- Intermediate stock of raw material 3 times smaller.

- ZINC ALUMINIUM IN A SINGLE BATH.

- 75% less zinc dross

- Complete lines up to 20 wires (2.300 Ton/month)

- Energy saving due to higher efficiency of the furnace(s). (up to 75%)

- Solutions from 1 wire (130 Ton/month) expandable to 10 wires (1.300 Ton/month).

- Very low «stand-by» energy consumption if the line is not producing (i.e. over weekends).

- The line can be transferred to another site in a very short time.

- Smaller zinc kettle (more than 90% reduction in zinc investment, 10 Ton (20.000€) vs 120 Ton (240.000€) In traditional Process).

- Plant space saving because of smaller footprint – 80 mts. GALVAGREEN vs 140 mts. traditional galvanization technology.

The line can be easily and efficiently stopped and started in a very short time, because of very low thermal inertia (the line is ready to run from «stand-by» mode in minutes); gas furnaces take days to reach operation temperature).

- Very low «stand-by» energy consumption if the line is not producing (i.e. over weekends).

- Technology designed from scratch to the most modern standard: less and easier maintenance, higher ergonomics, safer operation.

- Much higher quality of the annealing: exactly the required power to anneal the wire is applied to guarantee maximum quality, highest speed and lowest energy consumption.

- Independent thermal process parameters for each wire strand increase quality and reduce energy consumption.

- Higher operator productivity. (2-3 operators per turn plus a line supervisor, 19 people per month in GalvaGREEN vs 4-5 operators per turn plus line supervisor, 25 people in a traditional galvanizing line).

- Higher operator productivity. (150 Tons/month/operator GALVAGREEN vs 75 Tons old galvanizing technology)

- Lower conversion cost.

- ACID neutralization installation is not necessary.

- Lower installation cost. (80% less civil works), fast installation, less zinc stocked)

%

Less production cost

%

Less of space.

%

Less cost implementation

%

Less Dross Zinc.

%